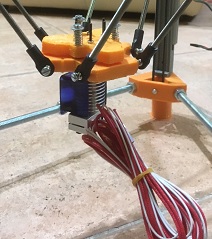

Step 1: Extruder Removal

The first step involved carefully removing the original extruder assembly while maintaining the delta mechanism's integrity.

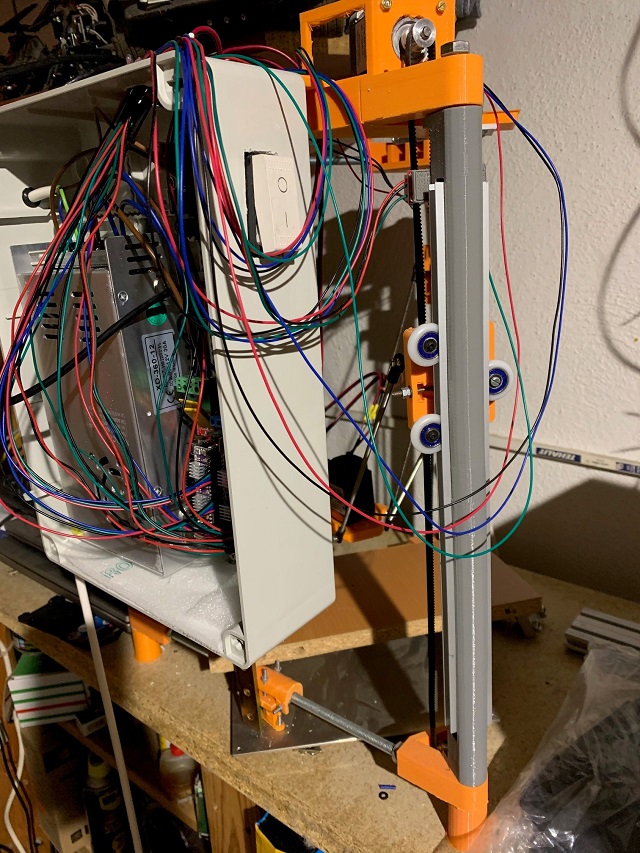

Converting a delta 3D printer into a powerful laser engraving system

Building on the success of the new Printerina 3D printer project, this modification transforms the compact delta printer into a versatile laser engraving system. By replacing the extruder with a 2500mW 445nm laser module, we've created what might be the first delta-based laser engraver.

The first step involved carefully removing the original extruder assembly while maintaining the delta mechanism's integrity.

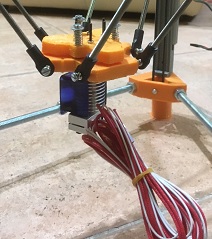

The 2500mW 445nm Laser Head Engraving Module was installed, featuring:

M106 S0

G92

G2

G1 X10 Y10 Z0

G4 P0

M106 S255

// ... calibration pattern ...

M106 S0A special calibration pattern helps find the optimal focal height for maximum cutting efficiency.

If you have specific questions about this project, please send me an email or leave a comment. I will reply as soon as I will be available.

If you need additional information or have questions about this project, feel free to reach out: write an email.